In the world of UltraLight LED lighting, the choice between edge-lit and back-lit LED panels is a common consideration. Both types have distinct designs and benefits, tailored to different lighting needs.

Back-Lit LED Panels:

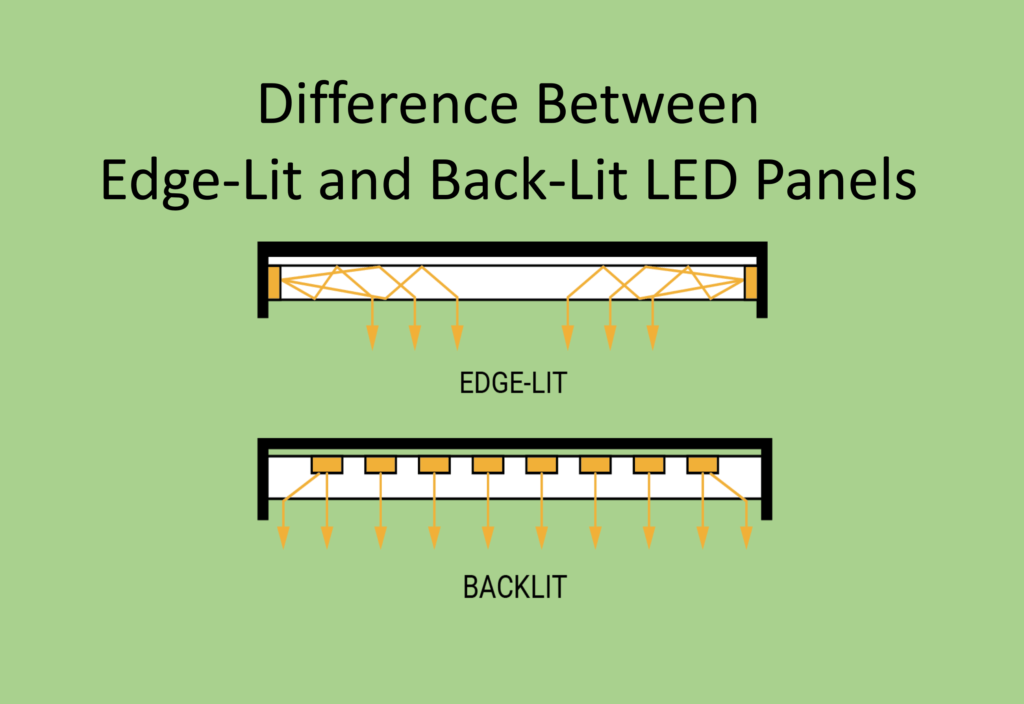

Back-lit LED panels, on the other hand, have LEDs arranged on a horizontal plate, shining light directly downwards through a diffuser. This method is also known as direct-lit LED lighting. The lack of an LGP in back-lit panels allows for a different distribution of light, leading to a more direct and often more efficient lighting output.

Edge-Lit LED Panels:

Edge-lit LED panels feature LEDs positioned along the edges of the panel. These LEDs shine horizontally into a light-guide plate (LGP), which then directs the light downwards through a diffuser. This setup creates uniform lighting, with edge-lit panels also being referred to as side-lit panels.

Which is Better: Edge-Lit or Back-Lit LED Panels?

Both edge-lit and back-lit LED panels have their pros and cons. Edge-lit panels were the first to be mass-produced, thanks to their innovative use of a light-guide plate (LGP). The LGP is effective in diffusing light evenly, reducing the risk of bright spots. High-quality LGPs made from acrylic (PMMA) are particularly valued for their high light transmission and resistance to yellowing over time.

However, in an effort to cut costs, some manufacturers use lower-quality materials like polystyrene (PS) for the LGP. These can yellow with age, leading to uneven lighting.

Back-lit LED panels have gained popularity due to advances in LED efficiency and lens technology. Modern adhesives secure lenses to each LED, ensuring even light distribution and reducing the risk of detachment—a common issue with earlier models. Micro-prismatic diffusers have also improved, making the double action of an LGP and diffuser unnecessary.

The market now embraces both designs, with companies like NVC offering both in their product range. However, edge-lit panels are often preferred for their superior driver placement, which helps keep the driver cool, extending its lifespan.

Potential Issues with Cheap Back-Lit LED Panels

While back-lit LED panels can be made more affordably due to the absence of an LGP, buyers should be cautious of low-cost options. Potential drawbacks include:

- Insufficient LEDs: Panels with too few LEDs (typically 36 or less) may require higher currents to achieve the desired light output. This can reduce efficiency, increase heat generation, and shorten the lifespan of the LEDs.

- Plastic Bodies: High-quality back-lit panels usually have a metal body that acts as a heat sink. Cheaper models with plastic bodies are less effective at dissipating heat, further reducing LED lifespan.

- Poor Light Distribution: In well-designed back-lit panels, each LED is lensed to ensure overlapping light distribution, providing even illumination. Poor lens design and a low number of LEDs can result in bright and dark spots.

- Weak Adhesives: Over time, heat can cause lenses to detach if cheap adhesive is used, leading to uneven light and potential glare.

- Built-In Driver: Some manufacturers save costs by integrating the driver into the panel body. However, this approach limits flexibility, making it impossible to replace the driver or offer dimming and emergency options.

UGR <19 Performance

Both edge-lit and back-lit LED panels can achieve excellent Unified Glare Rating (UGR) performance, especially with the right front cover. When comparing different UltraLight LED lighting options, always review the UGR tables included in the photometric data from reputable manufacturers.